Fuel Production

The Lab

How it's done

Heating & Filtering:

Used vegetable oil (UVO) is passed through a coarse filter as it is transferred from pick-up barrels to a heating drum. The oil is heated to 60°C for approximately four to five hours, to reduce viscosity and reach the activation energy necessary for the desired reaction to take place. It is then transferred to a second heating drum, where it is passed through a second series of fine filters that remove any remaining particulates. In this drum, the oil is heated again. Heating also serves a secondary function to remove water from the oil before reaction; any water that enters the reactor can often lead to saponification (undesirable process that produces soap) later on.

Mixing & Titration:

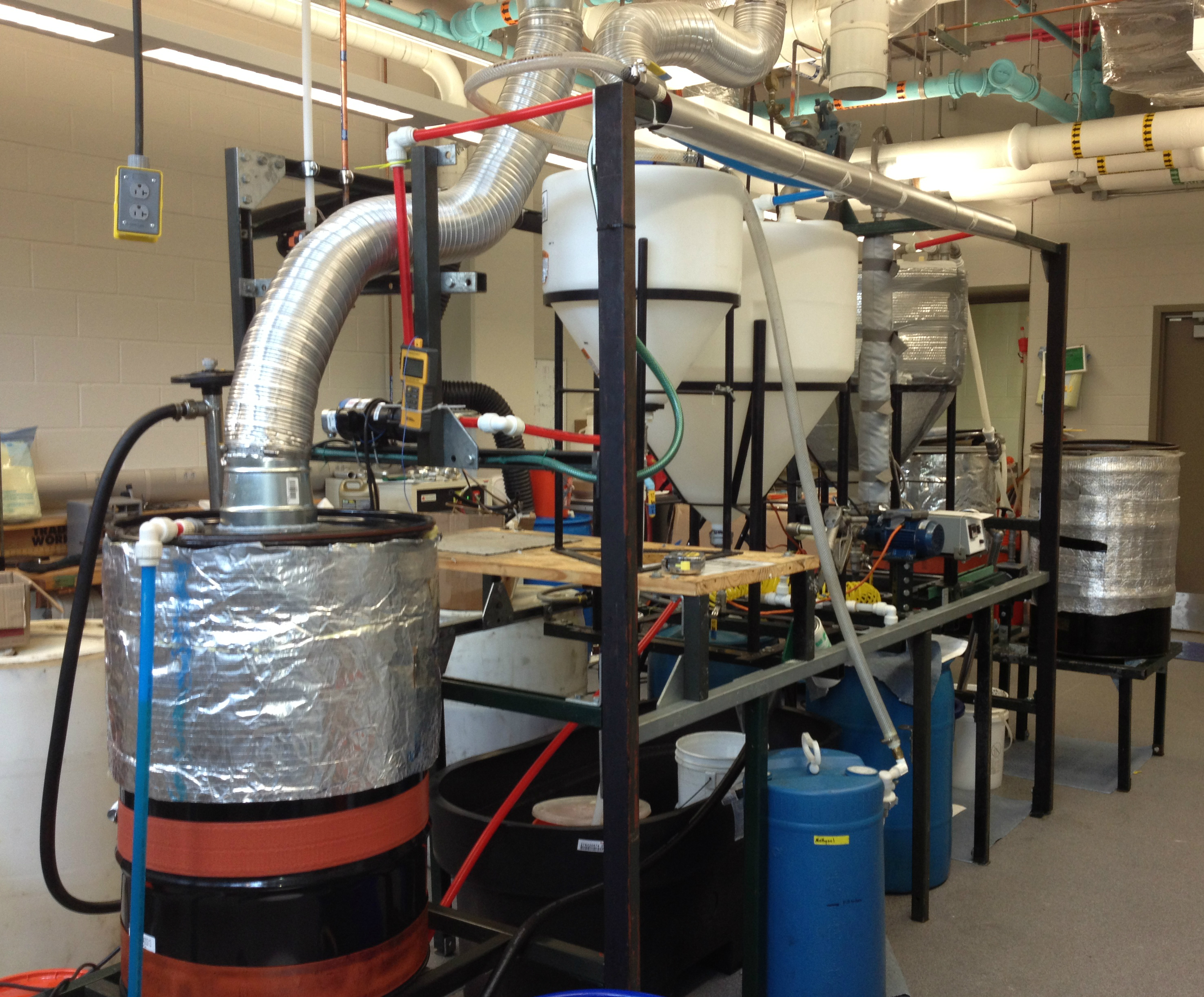

When the oil temperature reaches 60°C, 40 gallons of heated oil are transferred into an insulated reactor . There, the oil is mixed with nine gallons of methanol (approximately three times the stoichiometric ratio for the reaction) and a titration-based amount of potassium hydroxide (KOH) for approximately four hours. The methanol is added to contact the fatty acids and create methyl ester, and the potassium hydroxide is used as a catalyst to help the reaction take place and to stabilize the glycerin for soap production.

Settling & Washing:

![]()

At the end of the mixing cycle, the oil has been converted to biodiesel and glycerin. It is allowed to settle for 12 hours, during which, the denser glycerin sinks to the bottom, where it is removed and collected. The remaining biodiesel is then transferred directly to a second reactor. In a separate process, methanol is removed from the glycerin, and it is then used in the manufacturing of soap.

Once the glycerin is completely removed, the remaining biodiesel still contains impurities too small to have been removed during the initial filtering process – these impurities are removed in the washing (wet or dry) process. In the water (wet) wash process, the fuel goes through three washing stages. In each stage, 10 gallons of water are pumped into the reactor, where a mixer prevents separation. In addition to the water, 200 ml of glacial acetic acid is added to the first wash, and 100 ml of glacial acetic acid is added to the second wash. The glacial acetic acid is used to increase the hydrolysis of the remaining fatty acids in the biodiesel. The third wash is performed using only water. In each wash cycle, the biodiesel, water, and acid are mixed for at least 20 minutes, then allowed to settle for at least another 25 minutes. The water and acid are removed at the end of each wash cycle. After the final wash cycle, the mixture is allowed to settle for at least 12 hours, allowing particulates and water to separate out of the biodiesel so they can be removed. In the dry wash process, the biodiesel is passed through ion exchange towers containing cation resin. The resin helps to remove impurities from the fuel.

Drying:

To aid the evaporation of any remaining water, the biodiesel is pumped into the drying barrel shown in the picture. The fuel is heated to 60°C and flows from the bottom of the barrel through the pipe along the outside. It then flows up to a shower head at the top of the barrel just below the lid. The lid remains in place and a vent pulls air directly from the barrel. This process takes at least four hours.

Finished Product:

The finished B100 (100% biodiesel) is then pumped through a fuel filter and into a clean oil barrel for storage and further blending.