Testing

The Testing Lab

Testing Equipment:

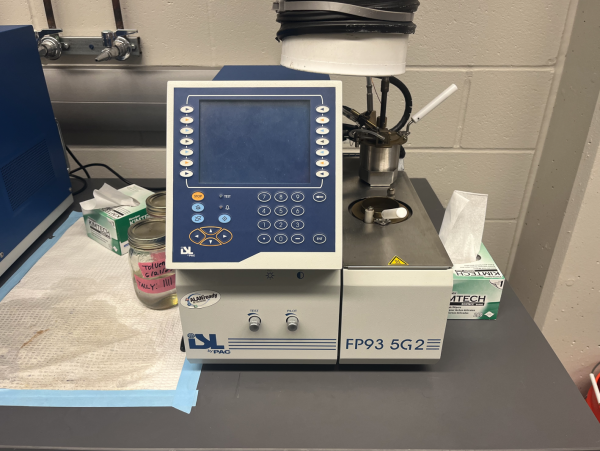

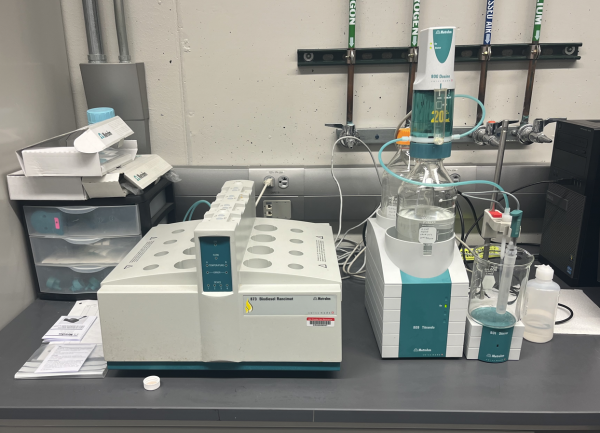

This test method specifies a procedure for the determination of the flash point of liquid petroleum products, by measuring the temperature at which the ignition is flashed when in contact with a flame. The expected flash temperature is determined at the beginning of the experiment. This is the minimum temperature in which the biodiesel sample is expected to trigger an ignition flash. The machine then slowly raises the temperature of the sample and periodically dips the flame into the sample to see if it will ignite. Flash point is used in shipping and safety regulations to define flammable and combustible materials and for classification purposes. This test method can be used to measure and describe the properties of materials in response to heat.

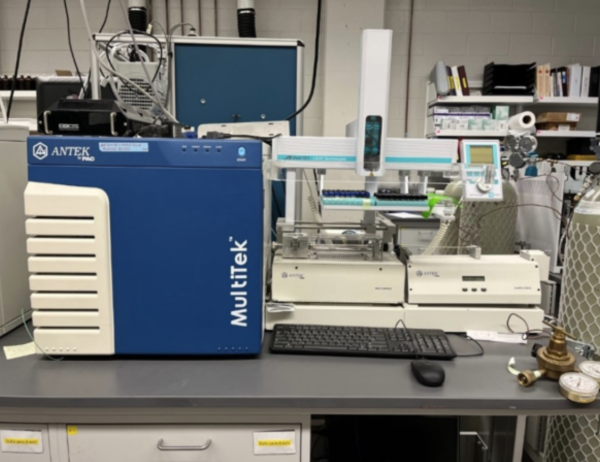

This machine is used to test the cold filter plugging point by testing what temperature the sample tested clogs the filter. A sample of the biodiesel is cooled and drawn up a pipet using a vacuum through a wire mesh filter. This occurs at every 1°C until the sample exceeds 60s to fill the pipet. The temperature at which this takes place is known as the CFPP. The information for this test is the lowest temperature at which the fuel will have trouble-free usage.

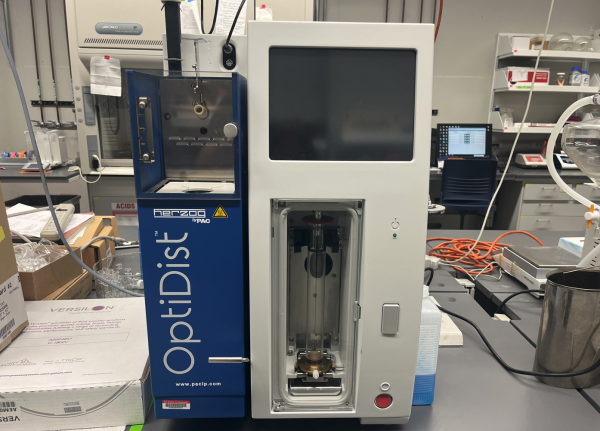

Cloud point is defined in petroleum products and biodiesel fuels as the temperature of a liquid sample when the smallest observable cluster of hydrocarbon crystals first forms upon cooling under a set of conditions. This test method determines the cloud point of liquid petroleum products by measuring the temperature at which the sample becomes cloudy. To begin a test jar containing the sample is inserted into the apparatus and the sample begins to cool incrementally. The sample is continuously monitored by a reflective optical system for the formation of crystalline structure. When crystallization of the wax is detected by the optical system, the temperature is recorded to within 0.1 °C resolution. Wax filters of sufficient quantity can plug filters used in some fuel systems.

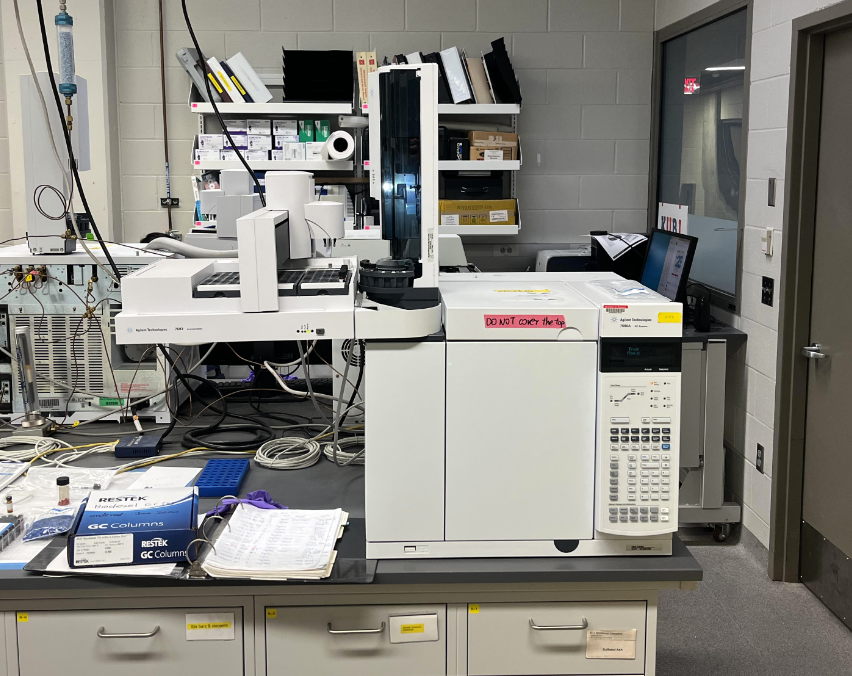

This test is used to determine the total monoglyceride, total diglyceride, total triglyceride, and free and total glycerin in the biodiesel using gas chromatography. A sample of the biodiesel is analyzed by gas chromatography, after silylating with N-methyl-N-trimethylsilytrifluoracetamide. Calibration is first done by using two internal standards and four reference materials. Mono-, di-, and triglyceride are determined by comparing to the mono-, di-, and triolein standards. Average conversion factors are applied, and the bonded glycerin content of the sample is calculated. It is important to know the free and bonded glycerin content as it reflects on the quality of the biodiesel. A high content of glycerin can cause issues of separation in the biodiesel. It can also lead to injector fouling and the formation of deposits in injection nozzles, pistons, and valves.

The viscosity test measures the time of a liquid to flow under gravity through a calibrated glass capillary viscometer. The method specifies a procedure for determining the kinematic viscosity, or resistance to flow, of liquid petroleum products. Determination of viscosity is essential in estimating optimum storage, handling, operational conditions, and lubrication of equipment.

This test measures the amount of sulfated ash in biodiesel. By heating the sample until there is only ash and carbon, the sample can be treated with sulfuric acid to oxidize the carbon. The leftover carbon is weighted and the amount of sulfated ash is determined. Sulfated ash can be an indication of metals present in the sample.

The oxidation stability test measures the induction period, time between when the test starts and the moment conductivity increases rapidly, using an electrode. By passing purified air through a sample, vapors released from the sample are collected into a flask with distilled water. During this oxidation process, carboxylic acids are produced through a process of hydrolysis. Hydrolysis occurs when water molecules break one or more of the chemical bonds in the sample, this increases the number of carboxylic acids and causes a rapid increase in conductivity. Using the induction time and van’t Hoff’s law, shelf life and storage temperature of the product are determined.

The Calorimeter machine is used to determine the heat of the combustion of the liquid fuel. The machine does this by burning a weighted sample in an oxygen bomb calorimeter in controlled conditions. The heat of combustion is then determined from the temperature of before, during, and after combustion. The heat of combustion is the energy available from the fuel. This is important to know for the thermal efficiency of the equipment for producing heat or power.

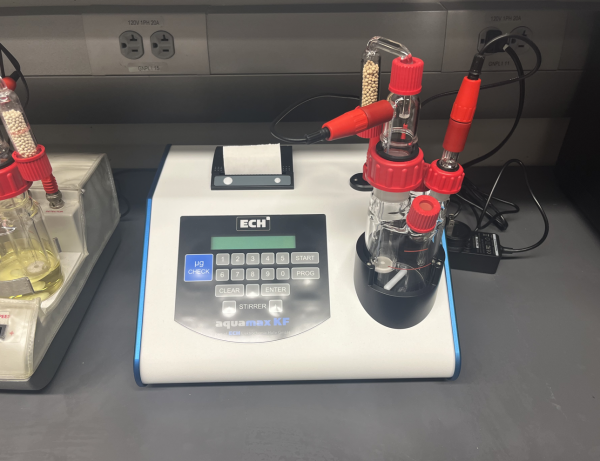

The Karl Fischer titration test is done to measure the water content in the biodiesel fuel by coulometric Karl Fischer titration. The test consists of an automatic titrator done with reagents. The titration consists of iodine being injected into the test sample, where it will then be consumed by a reaction with water. The completion of this reaction is detected by a platinum electrode. The water content in the biodiesel fuel is determined by the coulombs of electricity required to generate the necessary amount of iodine needed for the titration. Once the needed amount of iodine is found, the Faraday equation can be used to calculate the amount of water in the biodiesel fuel. The water content of biodiesel fuel needs to be known for a few different reasons. Water within the fuel reduces the heat of combustion, causes corrosion in fuel system components, freezes and crystalizes within the fuel, and accelerate growth of microbe colonies. A high-water content within a liquid can also change the electrical characteristics. This would create an issue for some electrical applications of the biodiesel fuel. The Karl Fischer test is conducted to confirm the water content of the biodiesel fuel is within the correct amount.